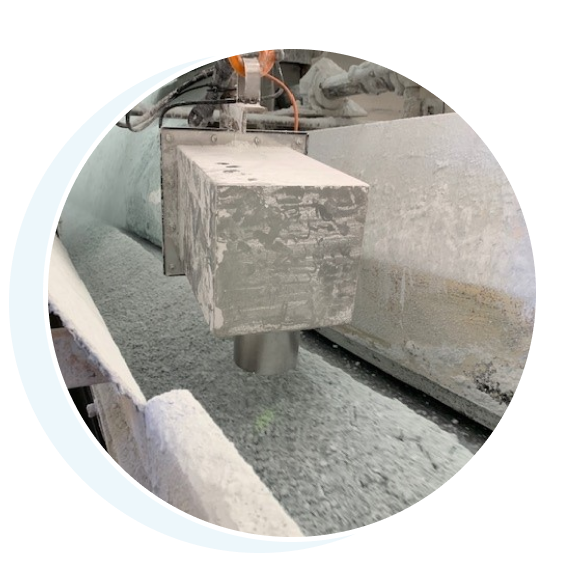

Online Near-Infrared IP-67 Waterproof/Harsh Conditions

IP-67 Rated Moisture Sensors

MoistTech’s IR3000-iP67 is an ideal solution for moisture measurement in harsh conditions. There are several benefits to installing an on-line, real-time moisture sensor, including reduced waste, higher product quality and better line efficiency. With experience in over 5,000 applications globally and thousands of equipment installs, MoistTech represents the diamond standard in reliable and dependable Near-Infrared moisture technology.

The 3000-iP67 online sensor:

- Stands up to wash-downs, dusty/dirty environments

- Is protected by effects of immersion

- Built with rugged stainless steel enclosure

- Can withstand aggressive process applications

- Holds up extreme temperatures: included with the 3000-IP67 sensor is an integrated air vortex or liquid cooling system that is rated from 0°C to 93°C (200°F)

- Insulation wraps & explosion proof enclosures are also available

Reliable and continuous moisture data allows the user to make adjustments in real time before simple fixes turn into issues resulting in scrap, downtime and setbacks. Each MoistTech sensor is calibrated prior to shipping and will not need future calibration, even with chances in material height, size or color. Enjoy a maintenance-free, drift-free optical design that accurately provides instant, repeatable results. State-of-the-art components allow the user to easily install the sensor in extreme operating conditions, without affecting the reading capabilities. Each sensor is equipped with plug-and-play technology for easy installation at almost any point on the line. With MoistTech’s advanced digital processing, the IR3000-iP67 provides true, exact data regardless of gaps and interruptions of product flow on the belt or screw conveyors.

Benefits:

Continuous moisture monitoring plays a role in keep product within spec, saving money on material waste, lowered fuel consumption and less water use, which optimizes plant efficiency. The revenue saved thanks to the moisture sensor results in instant ROI. Safety is also enhanced when a moisture sensor is in use. Monitoring moisture helps users maintain proper moisture levels, reducing the risk of explosions due to dust.

How does moisture affect production?

Product Quality Monitoring

Process Optimization

Fuel Savings

Water Savings

Dust Prevention

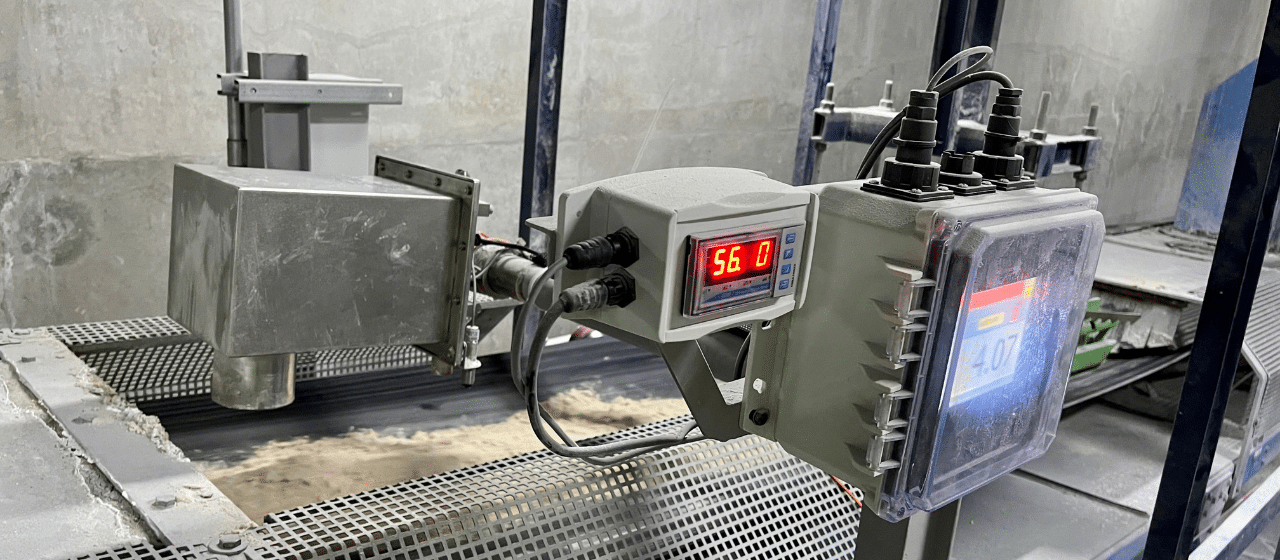

Installation Features

The sensors can be installed using the bracket on the back of the sensor 4” – 16” (inches) from the product. The MoistTech sensor has many options for installation including:

- Belt, Screw, Drag & Enclosed Conveyors

- Chutes, Cyclones & Bins

- Dryer In/Out

- Webs

- Pipeline or Pneumatic Conveying using our Flange Window or Sampler Cups

Near-Infrared

All molecular bonds absorb specific wavelengths of light. Hydrogen bonds including O-H (water); C-H (hydrocarbon) and N-H (ammonia) all absorb strongly in the NIR spectral region. The amount of NIR energy reflected at a given wavelength is inversely proportional to the quantity of absorbing molecules in a product.

The NIR technique is a non-destructive, non-contacting measurement. MoistTech’s sensor utilizes multiple wavelengths of NIR light, projected onto the product at a very high repetition rate. The reflected light is then measured using a digitally enhanced detection system and thousands of data points are sampled every second.

Management Software

MoistTech developed a collection of sophisticated Windows™ programs to supply straightforward user interfaces for setup, data logging, as well as tracking of diagnostics. With this you can perform calibrations, define gauge and measurement parameters, and set-up and configure up to 50 different product codes. The MoistTech Software package is easy to use and compatible with any PC platform.

Looking for a sensor that is explosion proof? We have you covered! MoistTech offers all of the amazing qualities of the NIR IR3000 sensor in an explosion proof housing – see more information here.