online near-infrared

ir-3000F: food products

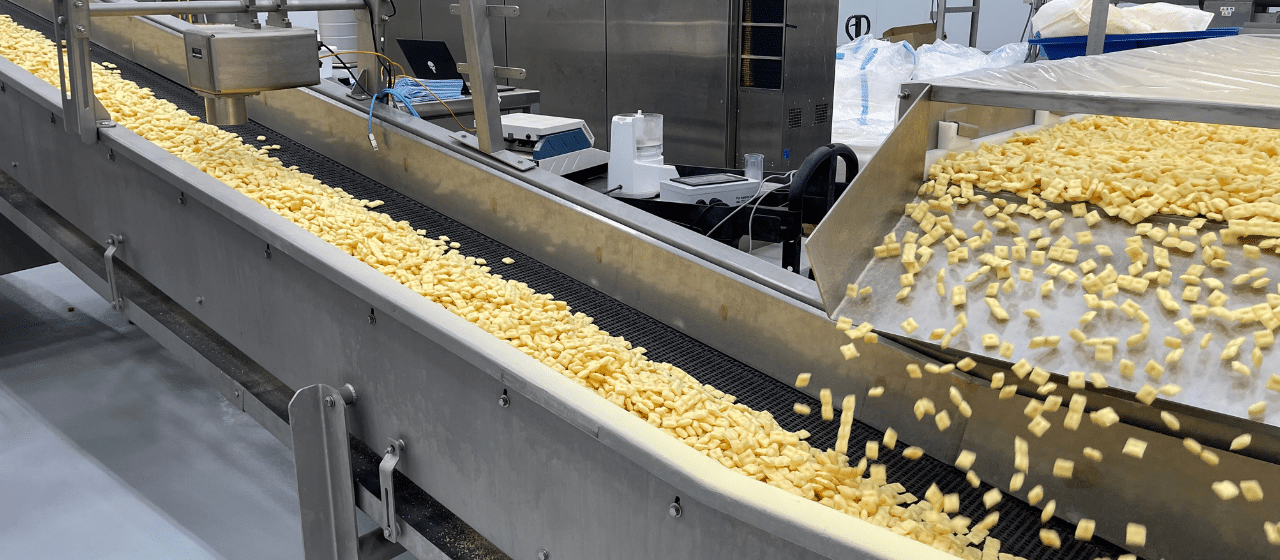

let moisttech help you improve the taste & quality of your products – popular installations include:

bakery dough

breadcrumbs

cereals

chocolate

coffee

cookies

cornmeal

crackers

dairy powders

dried fruit & vegetables

dried yeast

gelatin

grains

ground meat

nuts

olive pulp

pectin

potato chips

powdered drinks

salt

sausage & deli meat casings

soup powder

soy

spices

sugar

tea

and more!

Evaluating the manufacturing process to implement cost-effective improvements allows for a multitude of benefits. Accurately measuring the food product moisture, protein and fat/oil content can have drastic effects on the manufacturing process. Having an accurate reading to rely on throughout the food and baking process is one of the most critical components in the industry. MoistTech manufactures the diamond standard in moisture analyzers, providing users with an accurate test of the moisture levels in the manufacturer’s raw ingredients, which effectively saves purchasing plants a lot of money.

Multiple stages of the food process require moisture measurement and control as variations and excess moisture in mixes can result in clumping and out of spec recipe formulas. Testing food moisture during this time will allow adjustments to be made throughout the mixing process, thus improving the quality of the final product.

While moisture is our major focus, we also supply analyzers for the continuous online measurement of protein, fat/oil, sugar, seasonings, caffeine and other constituents/elements that absorb the NIR beam.

Numerous years of experience provides MoistTech with thousands of installations worldwide in a wide variety of food products, from slurries to powders. Offering both on-line continuous readings and laboratory moisture sensors for spot tests near lines provides the user with full product inspection.

Realizing that many food processing companies use many primary reference measurements, either in-house or out sourced, MoistTech’s NIR moisture sensors are easy to set-up and use which will provide instant and precise measurements due to no constituent losses in handling. With instant measurements provide manufacturers savings in analysis cost, delivering times and shipping costs.

Our food moisture sensor calibrations, measurement wavelengths, algorithms and sensor optical requirements are pre-set at the factory. On moisture analysis involving dried products, accuracy can be expected to be 0.1%. On higher moisture applications, accuracy can be expected to be 0.2 and 0.5%. Fat/oil measurement and protein accuracy are subject to application.

Installing Precise Control

Immediate ROI is seen with the installation of a moisture measurement system as the plant controllers can instantly make any process adjustments and can see the redcued waste and energy usage and overall increase in quality and efficiency. Food sensors are recommend for installation:

- exit of the ovens, fryers, dryers, etc.,

- close to packaging so that it will allow the food time to stabilize while cooling

- blender inputs and outputs

- production lines

- belt, screw, drag & enclosed conveyors

- chutes, cyclones & bins

- pipeline or pneumatic conveying

sensor features

Users can enjoy many features of MoistTech’s IR-3000 sensor that can immediately benefit the production line. Easy to use and incorporate into many existing systems, we are proud to offer the following features with our IR-3000 series sensors:

pre-calibrated to your application without calibration drifting

optical window contamination alarm/monitor

insensitive to ambient temperatures & lights

store up to 50 different product codes/calibrations

windows operating software for management & control

3 x 4-20mA outputs available

0-10V available

sapphire, kel-F, & Quartz sensor window options

optional explosion proof enclosure

benefits

blending monitoring

reduced energy usage

higher quality product

plant production efficiency monitoring

100% product inspection

increased productivity

reduce / eliminate down time

eliminate product waste

product consistency

more options

converting products

Our IR-3000C product sensor can measure moisture, coat weight, thickness and temperature in convering applications.

coke/coal/sinter products

Specifically designed for the dark mineral industry, the CCS-3000 series can measure moisture in dark materials.

IP-67 rated sensor

Ideal for harsh conditions, the IP-67 rated sensor can withstand wash-downs, and aggressive process applications.