online near-infrared

IP-67 waterproof/

harsh conditions

ip-67 rated moisture sensors

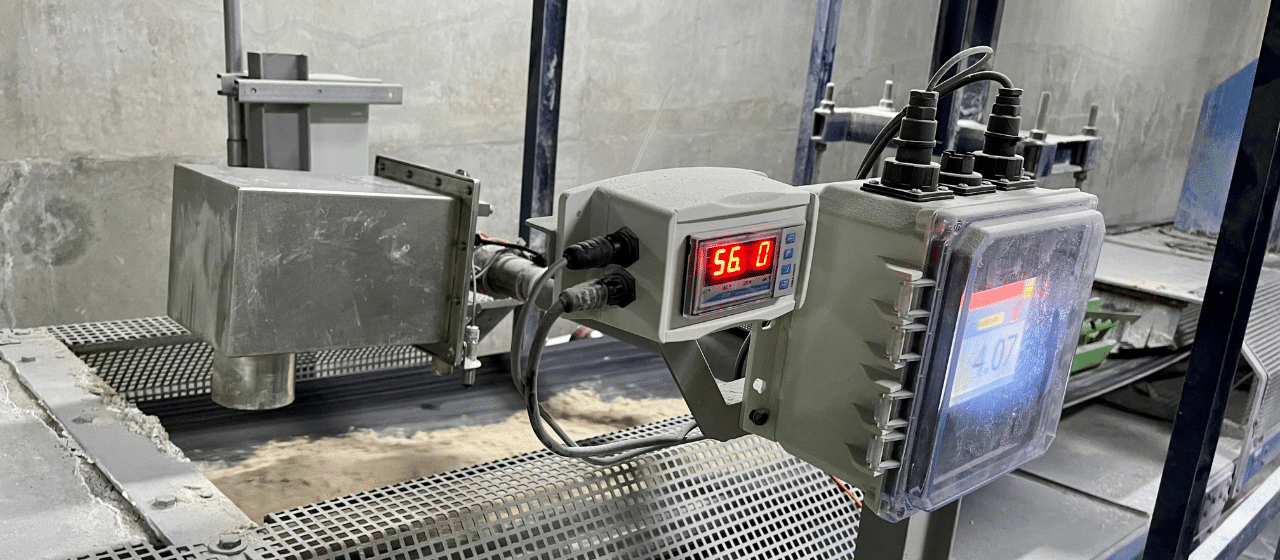

MoistTech’s IR3000-iP67 is an ideal solution for moisture measurement in harsh conditions. Increasing production efficiency with proper moisture control provides multiple benefits to the user: energy & fuel savings from proper dryer control, lower material losses, total monitoring of manufacturing process and overall plant effectiveness.

With experience in over 5,000 applications globally and thousands of equipment installs, MoistTech represents the diamond standard in reliable and dependable Near-Infrared moisture technology.

The 3000-iP67 online sensor:

- stands up to wash-downs, dusty/dirty environments

- is protected by effects of immersion

- built with rugged stainless steel enclosure

- can withstand aggressive process applications

- holds up extreme temperatures: included with the 3000-IP67 sensor is an integrated air vortex or liquid cooling system that is rated from 0°C to 93°C (200°F)

- insulation wraps & explosion proof enclosures are also available

Providing a reliable and continuous moisture content reading of the material gives the user full control over the manufacturing process to make necessary adjustments. With a one-time calibration done proior to shipping, MoistTech’s sensors are unaffected by material changes such as size, height and color. Enjoy a maintenance free, drift free optical design that accurately provides instant, repeatable results.

State-of-the-art components allow the user to easily install the sensor in extreme operating conditions, without effecting the reading capabilities. With MoistTech’s advanced digital processing, the IR3000-iP67 provides true, exact data regardless of gaps and interruptions of product flow on the belt or screw conveyors.

How Does moisture effect production?

Product quality monitoring

Increase the consistency of product quality with constant moisture monitoring

process optimization

Full plant efficiency control to allow for 100% monitoring of the production process

fuel savings

Reduce the energy usage of the drying process by controlling moisture content, resulting in a reduction in energy consumption

water savings

Reduce your water usage by continuously monitoring moisture content

dust prevention

Help reduce the risk of explosions due to dust

installation features

The sensors can be installed using the bracket on the back of the sensor 4” – 16” (inches) from the product. The MoistTech sensor has many options for installation including:

belt, screw, drag & enclosed conveyors

chutes, cyclones & bins

dryer in/out

webs

pipeline or pneumatic conveying using our flange window or sampler cups

near -infrared

All molecular bonds absorb specific wavelengths of light. Hydrogen bonds including O-H (water); C-H (hydrocarbon) and N-H (ammonia) all absorb strongly in the NIR spectral region. The amount of NIR energy reflected at a given wavelength is inversely proportional to the quantity of absorbing molecules in a product.

The NIR technique is a non-destructive, non-contacting measurement. MoistTech’s sensor utilizes multiple wavelengths of NIR light, projected onto the product at a very high repetition rate. The reflected light is then measured using a digitally enhanced detection system and thousands of data points are sampled every second.

benefits

product quality monitoring

Allows immediate production line adjustments to improve product quality & consistency

process optimization

Allows 100% monitoring of the production process to reduce product that is “out of specification”

fuel consumption savings

Reduce the energy usage as the drying / cooking process can be controlled by the moistue sensor, resulting in a reduction of energy consumption

low cost - immediate return on investment

highest accuracy utilizing near-infrared technology

easy installation & one-time calibration

newest technology & software updates

very low to zero maintenance needed

surface mount electronics

dust prevention

Help reduce the risk of explosions due to dust

management software

MoistTech developed a collection of sophisticated Windows™ programs to supply straightforward user interfaces for setup, data logging, as well as tracking of diagnostics. With this you can perform calibrations, define gauge and measurement parameters, and set-up and configure up to 50 different product codes. The MoistTech Software package is easy to use and compatible with any PC platform.

Looking for a sensor that is explsion proof? We have you covered! MoistTech offers all of the amazing qualities of the NIR IR3000 sensor in an explosion proof housing – see more information here