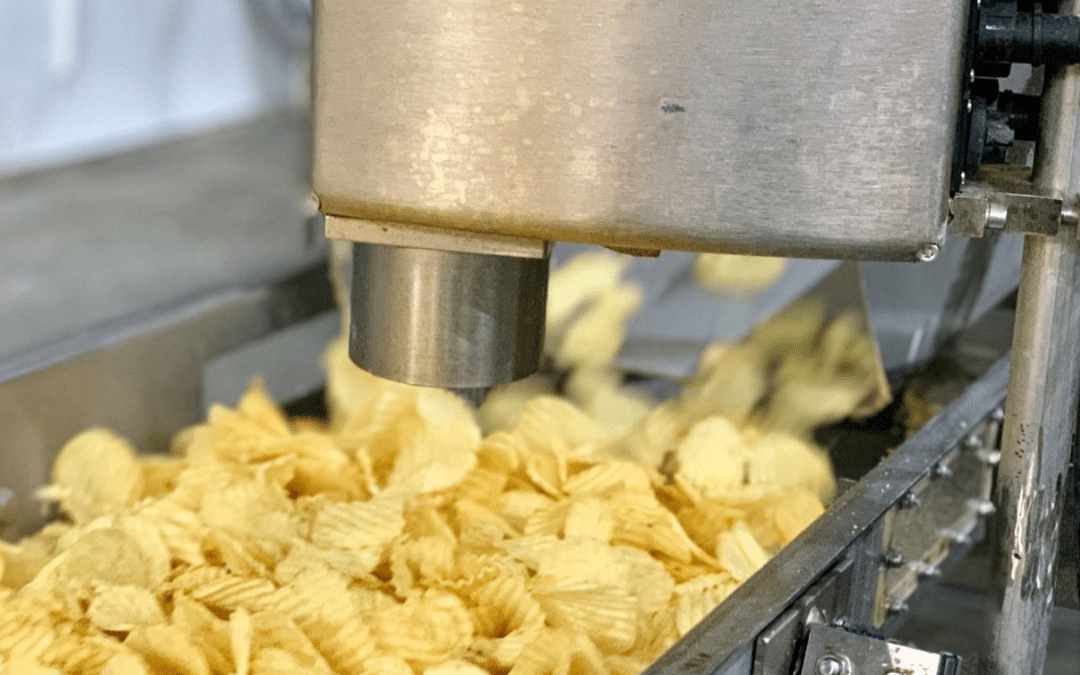

When we think of food, moisture appears to be a good aspect for quality products. Images of juicy steaks, moist grilled chicken and soft cake come to mind. However, too much moisture can be an issue for certain foods. No one wants soggy cracker or potato chips. If there is too much moisture in dried fruit, your chewy snack can turn into a mushy mess. For the best product quality, foods need an accurate amount of moisture for each product type during production. When moisture levels are inaccurate on a food processing line, several problems arise. Product quality, loss, energy use, waste and consistency are some aspects that raise a level of concern when it comes to moisture content. By implementing a moisture measurement sensor on your processing line, changes in moisture data can be recognized and corrected before the product is affected.

Product Quality Issues with Moisture Content

Product quality is one of the most notable issues with inaccurate moisture content on food processing lines. If there is too much moisture, the product can be soggy or fall apart. When the moisture content is too low, food products can become dried out or brittle. Products are of the best quality when the moisture content is precisely where it should be. Testing moisture content with other methods involves collecting a sample, which can slow down production. With this methods, it can take longer to identify any moisture changes, which means more product is affected. MoistTech’s IR-3000 on-line moisture sensor collects data in real time. No line downtime is needed to gather data. Since data are instantly available, the operator can make adjustments quickly to prevent a dip in product quality.

Moisture Content Affects Loss

Loss can result from inaccurate moisture content. This can be in the form of product loss, time loss and revenue loss. If inaccurate moisture levels are left unchecked for too long, it may be necessary to dispose of the product. Excessive moisture can lead to clogged equipment. The resulting downtime to clean or repair the equipment is a loss of time and efficiency. Whenever there is product or time loss, it also affects revenue due to production being off schedule. Installing a moisture monitoring sensor is a proactive approach to reducing loss on food processing lines.

Excessive Moisture Leads to Energy Use

When there is too much moisture in food products, it can lead to excessive energy use. Equipment, such as ovens, needs to be used for longer periods of time to dry out the extra moisture. This contributes to increased energy consumption that impacts revenue. By ensuring moisture content of products remains at optimal levels, equipment can be used efficiently to reduce energy use.

Prevent Material Waste with Moisture Monitoring

Material waste is a major concern for food processing lines that experience inaccurate moisture levels. When the moisture content is inconsistent, materials and even completed products may be wasted if the issue is not caught in time. If a line does not measure moisture content throughout the production process, there is a great risk of material waste in the event of inaccurate moisture in the finished product. When moisture levels are detected early in the production process, changes can be made to reduce or eliminate the need for product waste.

Moisture Measurement Ensures Product Consistency

If a product is not consistent, it is hard to gain loyal customers. Buyers want to depend on products to be consistent with every purchase. Maintaining the correct moisture content plays a critical role in product consistency. The moisture content in food can impact aspects such as texture, taste, appearance, shelf life and microbial stability. Consumers want to be assured that the food products they are purchasing meet safety standards. Give them peace of mind with your product by measuring the moisture content to ensure consistency and quality. When moisture content is inconsistent, it affects the product consistency. Continuously monitoring moisture will help keep products consistent, which will retain loyal customers.

MoistTech is Your Partner in Food Processing Moisture Monitoring

MoistTech’s IR-3000 moisture sensor can improve your food processing line. The sensor continuously collects data for instant discovery of any moisture level discrepancies. After the initial calibration, it will never need calibrating again. It is guaranteed never to drift, so you will always have accurate readings. The non-contact design means no wasted product for samples. Find out more about how our moisture sensors support the production of human foods.