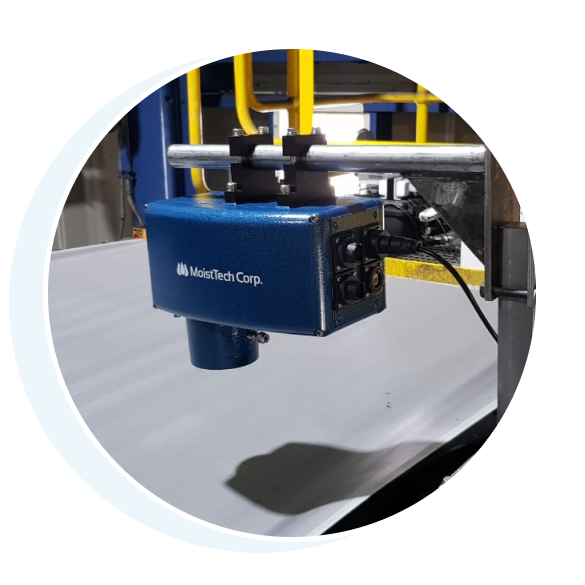

IR-3000

Near-infrared

Diamond Standard Equipment, Service & Support

MoistTech is recognized as the global leader in the moisture measurement industry. Utilizing state of the art NIR (Near Infrared) technology allows the user to achieve the highest quality product from accurate, real time data. The IR-3000 series are the flagship sensors providing an on-line moisture analysis for instant, non-contact measurement of virtually any product and raw material. Unsurpassed in performance, stability, reliability, maintainability and cost of ownership, the IR-3000 is the answer to controlling moisture in your product and increasing efficiency in your manufacturing line.

The IR-3000 is strategically designed to ignore material height or color changes while providing a continuous, reliable reading that calculates thousands of measurements per second.

There is a one-time calibration done in the factory based off your exact application, a virtually maintenance free setup allows for ease of use and a drift free optical design provides operating personnel with confidence make immediate process adjustments based on real-time measurements.

Real time process control can provide a manufacturer with the ability to make immediate changes without stopping the production line, and provides both energy savings and a potential for increased productivity with lower material losses.

The IR-3000 uses the most advanced components allowing installation in multiple locations locations and is equipped with product loss software capability where small gaps, inert material, foreign objects, belt or screw conveyors are removed from the measurement calculation, thus providing the most accurate true moisture reading.

Sensor Features

Users can enjoy many features of MoisTech’s IR-3000 sensor that can immediately benefit the production line. Easy to use and incorporate into many existing systems, we are proud to offer the following features with our IR-3000 series sensors:

- Pre-Calibrated To Your Application Without Calibration Drifting

- Optical Window Contamination Alarm/Monitor

- Insensitive To Ambient Temperatures & Lights

- Store Up To 50 Different Product Codes/Calibrations

- Windows Operating Software For Management

- 3 × 4-20mA Outputs Available

- 0–10V Available

- Sapphire, Kel-F, & Quartz Sensor Window Options

- Optional Explosion Proof Enclosure

Installation

The IR-3000 sensor has many installation locations using the bracket on the back or top of the sensor enclosure. Most typical installations are mounted 4”-16” from the product flow to be measured. Changes in product flow can be compensated for using our filtering, dampening and averaging.

Sensor Features

- Product Quality Monitoring: Allows immediate production line adjustments to improve product quality & consistency

- Process Optimization: Allows 100% monitoring of the production process to reduce product that is “out of specification”

- Fuel Consumption Savings: Reduce the energy usage as the drying / cooking process can be controlled by the moisture sensor, resulting in a reduction of energy consumption

- Low Cost – Immediate Return On Investment

- Highest Accuracy Utilizing Near-Infrared Technology

- Easy Installation & One-Time Calibration

- Newest Technology & Software Updates

- Very Low To Zero Maintenance Needed

- Surface Mount Electronics

- Dust Prevention: Help reduce the risk of explosions due to dust