News & Events

How Real-Time Moisture Monitoring Supports Lean Manufacturing

Lean manufacturing minimizes waste and maximizes value. One often overlooked but powerful tool in this process is real-time moisture measurement. Receiving consistent data regarding moisture levels allows for adjustments to be made immediately, which cuts down on...

How Moisture Monitoring Prevents Shrinkage and Color Defects

In the textiles and fabrics industries, product quality is paramount. If products do not meet set standards, recycling or discarding may be the only options. Moisture content plays an important role in the product quality of textiles. It can affect the quality,...

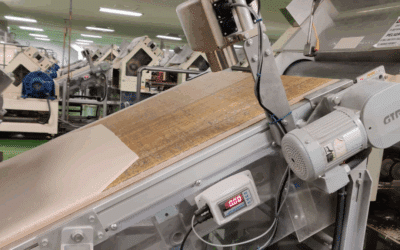

Why Accurate Moisture Measurement Is Essential for Quality and Efficiency in Industrial Baking

The benefits of the IR3000 extend beyond moisture measurement, contributing to overall process optimization and cost reduction. By enabling real-time adjustments to production processes, operators can proactively address issues and minimize downtime and waste....

Enhancing Efficiency and Cost-Savings with MoistTech’s IR3000 Series Moisture Sensors

In the dynamic landscape of modern manufacturing, where efficiency and cost-effectiveness are paramount, MoistTech Corp. emerges as a global leader in moisture measurement and control solutions. Their cutting-edge IR3000 series moisture sensors exemplify innovation,...

Why Continuous Moisture Monitoring Is a Game-Changer for Modern Manufacturing

The High Cost of Moisture Inconsistencies in Manufacturing As manufacturing grows more competitive, precision has become a non-negotiable part of staying ahead. One often-overlooked factor that can significantly affect product quality and production efficiency...

Increasing Snack Food Production with Moisture Measurement

Collecting moisture and oil measurements during snack food production can offer several benefits. When moisture and oil data are available in real time, the operator can make adjustments quickly to resolve any issues. This leads to improved product quality, less waste...

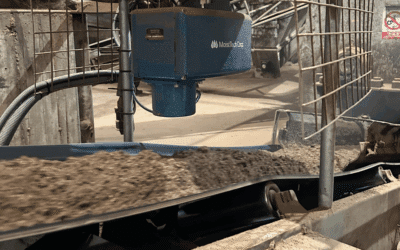

Reducing Energy Costs in Powders and Bulk Solids Production Processes

Powder and bulk solids manufacturers can incur high energy rates due to the nature of production. From industrial dryers to rotary kilns, there are several pieces of essential equipment that consume high volumes of energy. When the material has an improper moisture...

Moisture Measurement Can Prevent Dust Explosions in Powder Bulk Solids Industry

Improper Moisture Control Contributes to Dust Explosions Precision moisture control plays a significant role in the powders and bulk solids industries. If a line has improper moisture levels, it can lead to product waste, unnecessary downtime and even safety...

Precision Moisture Measurement for Food Manufacturing Company Case Study

Precision Moisture Measurement In food production, it is important to have correct levels of moisture. Too much or too little moisture can affect product quality. By using a MoistTech moisture sensor on-line, moisture levels can be adjusted in real time, which leads...

Precision Moisture Measurement for Wood Manufacturing Company Case Study

Precision Moisture Measurement Inaccurate moisture levels can lead to multiple issues in the wood manufacturing industry. By using a precision moisture sensor from MoistTech, the moisture levels can be measured, and alterations can be made as needed. The sensor can...