Neoprene Moisture

Why Control Neoprene Moisture?

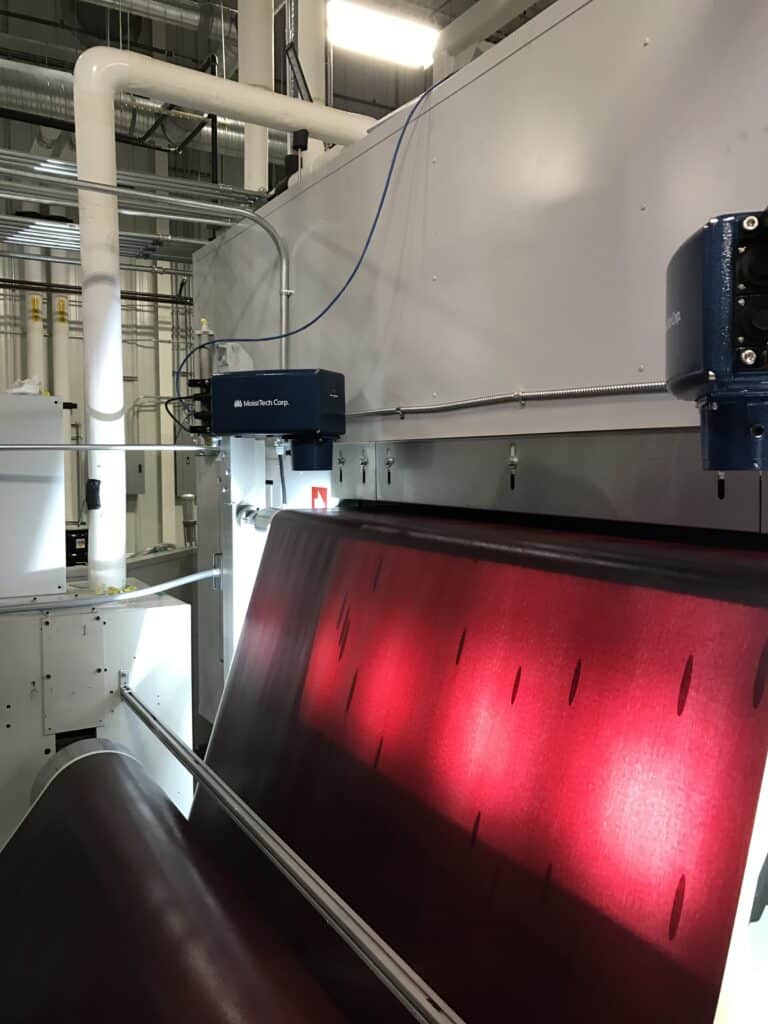

Neoprene has become an extremely important and popular polymer-based textile used in everything from wetsuits and athletic clothing to industrial gaskets and musical instrument components. Its thermal insulating and moisture wicking properties, accomplished by foaming its native rubber-like material with nitrogen gas, make it an extremely versatile product. As with any textile manufacturing process, controlling neoprene moisture during production is critical to the product’s final quality.

Controlling moisture during any textile production process is critical. By accurately and reliably measuring moisture, producers are able to achieve and maintain ideal textile quality and consistency. Because moisture content varies widely in raw materials and at different points in the production process, a moisture measurement system that can collect data at any point of the process is essential. Also essential is a system that achieves reliable and accurate non-contact moisture measurements.

Discover Precise Measurements Now!

non-contact

Our equipment never comes into contact with the product, allowing for less waste

zero drift

Our sensors are guaranteed not to drift over time – which saves time and money

closed loop

Create a closed-loop process by tying a moisture sensor into your PLC. Full control over the line!

no recalibrations

We’ve mastered the art of moisture sensors – your unit will never need to be recalibrated for the same product twice!

What is the Solution?

Reliability – the IR-3000 is pre-calibrated to measure neoprene moisture at the factory. It does not need re-calibration or other tedious maintenance once installed.

Technological Advancement – the IR-3000 communicates via laptop computer, PC-based touch screen operator interface, or plant-wide network through RS232/422/485 and Ethernet TCP/IP. MoistTech continually develops new protocols to keep pace with environmental conditions and technological advancements. Current I/O includes 3 x analog outputs 4-20mA isolated, self-powered.

Assess

Locate the point in the production process in which measuring moisture will be the most crucial and beneficial. Identify how you will use the moisture measurement data for improvements and if it will tie into your PLC.

Remember this could involve more than one installation point!

Contact

We offer service and support throughout the world for our moisture measurement sensors and would be happy to connect you with a rep in your area. Contact us today for more information!