properly install a moisttech sensor

Installation locations

Ideal Locations to Properly Install Moisture Control

The MoistTech 3000 series sensors has many installation locations using the bracket on the back or top of the sensor enclosure. Most typical installations are mounted 4’’-16’’ from the product flow to be measured. Changes in product flow can be compensated for using our filtering, dampening and averaging.

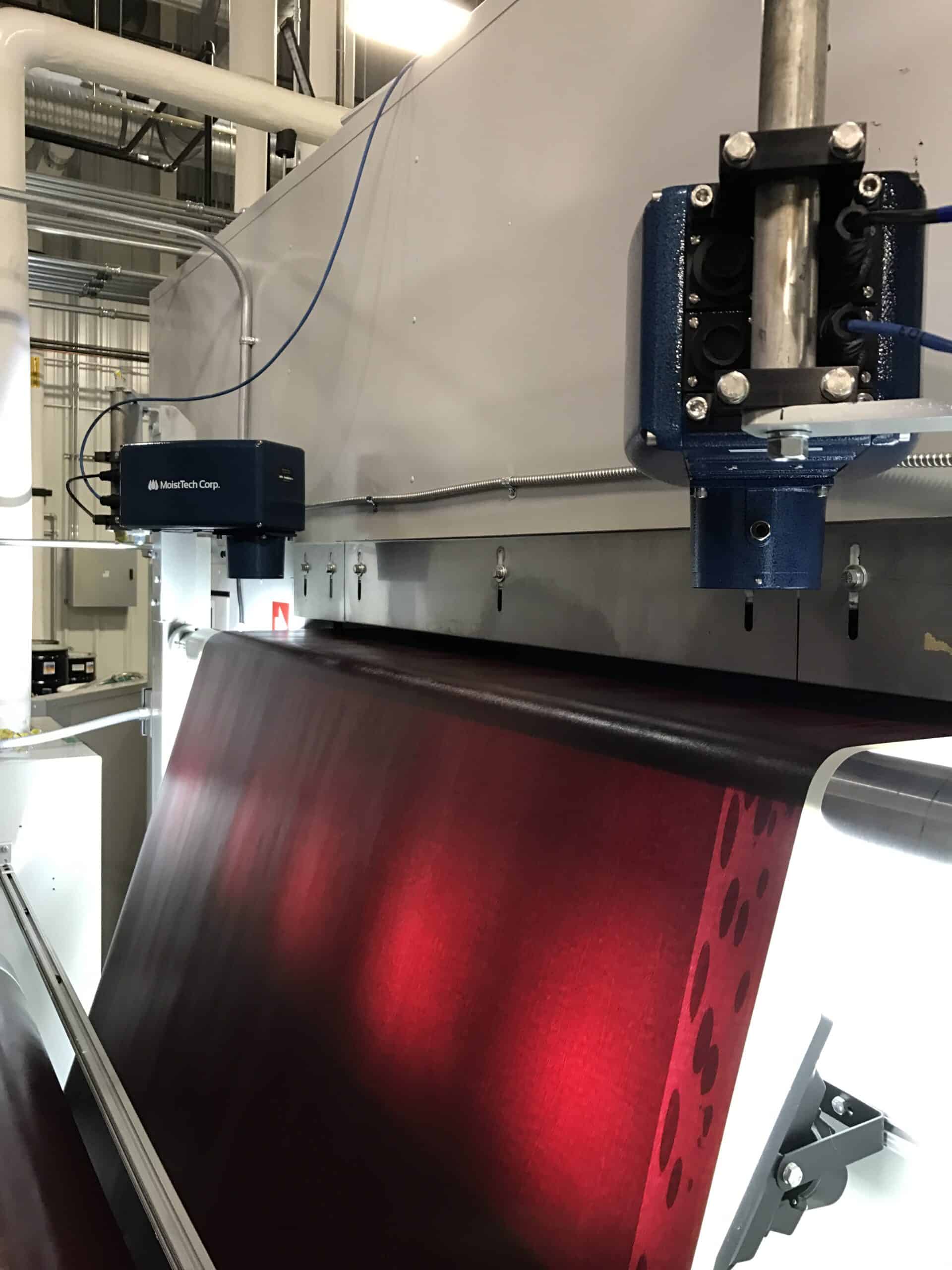

Belt installations

The most common and standard for the 3000 series sensor; mounted 4’-16’ above the product flow, the sensors instantly monitor the moisture with hundreds of measurements per second. These sensors can be open air or enclosed.

Screw conveyors

Screw conveyors are used in many bulk handling industries. Often used as an efficient way to move semi-solid materials, including food waste, wood chips, aggregates, cereal grains, animal feed, boiler ash, meat and bone meal, municipal solid waste and many others. The 3000 series sensors are positioned to measure in the flow of material just off the shaft of the auger while the embedded software dismisses the flight of the screw as it passes the optical path.

Many other types of conveying systems are available as suitable locations for installation and measurement. These consist of but not limited to chute, roller, chain, drag and elevator conveyors.

chutes, cyclones & bins

Cyclone, chutes and bin conveyors are common utilizing the MoistTech sampler cup, snorkel sampler, or flange window. This option keeps the 3000 series sensor externally mounted.

Many applications require instantaneous measurement in mixers and pug mills. These locations can be kept clean as the requirement is 4’ opening for the optical measurement.

web, converting & coating

Generally the 3000 series sensor is located in the most critical stages. However, the location is often determined by the space availability as well as manufactures’ requirements. The 3000 series can be implemented as a standalone sensor for single point measurement or positioned on a cross profiling measurement system.

Pipeline or pneumatic conveying with Flange window option

MoistTech sensors are not limited to the type of installation and can be mounted in any orientation using many of our measurement accessories.

Many locations thought to be inaccessible now provide MoistTech with an installation option. Large pipeline locations can be measured using a MoistTech Flange Window. Many products gravity fed or pneumatically conveyed are measured using the snorkel and sampler cup accessories. Product collects in the sampler cup and measured before air purges the sample back into the process repeating the measurement.

In addition to the MoistTech management software, we offer several read-out options to display and/or adjust the measurement outputs:

additional options

MoistTech offers numerous add-on options in addition to a moisture sensor to enhance the production line to each customer’s needs.

product temperature sensor (non-contact)

For online installations. An internally mounted pyrometer can be used to monitor the product surface temperature from 0-100C.

transmission adapter

Installed in place of standard light tube. For horizontal measurement for moisture and thickness

base & stand for on-line sensor

Gives the on-line moisture sensor the ability to be an off-line table top mounted sensor.

stainless steel / electro nickel enclosures

Optional enclosures for Food Grade application and Harsh Environments requiring specific IP classification.

valve cell for pipeline installations

3” Stainless Steel valve cell with Sapphire Window. Assembly with sensor can be mounted in any orientation.

product loss sensor (proximity detector)

Industrial processes will not always have a continuous flow of product. The optional product loss sensors trigger the online sensor measure on/off based on product visibility. Sensors are mounted on the sensor head and adjustable to maximize the best material flow.

profibus, profinet, ethernet IP, Devicenet

Communication outputs available above our standard 4-20mA, Serial and Ethernet TPC/IP

kel-f, quartz, sapphire viewing windows

Optional viewing windows available for applications requiring specifically designed glass or Kel-F plastic for Food Applications.

internal heater

Option for installation in cold climates below freezing. Optional 75watt heater cartridge with Thermo Switch for auto on/off regulation. Temperature range operational at 40F to 60F. Important to keep MoistTech sensors powered on in freezing temperatures.