Oriented Strand Board Moisture (OSB)

Maximum Profits & Efficiency with MoistTech Corp

Achieving optimal oriented strand board moisture in both infeed and outfeed processes translates to superior resin addition, reduced energy consumption, and the production of high-quality material before blending. Fiber quality is directly influenced by moisture content, and inaccurate moisture resin addition not only results in wasted money but can also cause severe process interruptions.

Precise control of raw material fiber not only enhances resin addition but also yields additional benefits, contributing to high-quality board properties. Resin moisture addition, when controlled accurately, results in significant cost savings. The major advantage occurs on the forming line, preventing downtime due to blown boards, a common issue caused by high oriented strand board moisture content furnish.

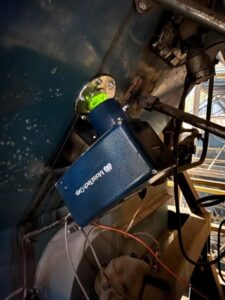

MoistTech has introduced the IR-3000 OSB moisture sensor, ideally suited for measuring moisture levels in the OSB process.

Discover Precise Measurement Now

non-contact

Our equipment never comes into contact with the product, allowing for less waste

zero drift

Our sensors are guaranteed not to drift over time – which saves time and money

closed loop

Create a closed-loop process by tying a moisture sensor into your PLC. Full control over the line!

no recalibrations

We’ve mastered the art of moisture sensors – your unit will never need to be recalibrated for the same product twice!

Benefits to OSB Moisture Control

Our sensor calibrations, measurement wavelengths, algorithms, and sensor optical requirements are factory pre-set. Typical accuracy is about ±0.1% moisture, with a typical analog range of 0-20% moisture. Outputs can be adjusted to optimize PLC or recording requirements.

A multitude of benefits become immediately noticeable with the implementation of a proper moisture measurement and control system:

- Increased Efficiency

- Improved Product Quality

- Lower Energy Costs

- Reduced Start-up Times

- Less Waste & Downtime

- 100% Product Inspection

- Significant Resin Cost Savings

Installation Points

Mounting the IR-3000 Oriented Strand Board Moisture Sensor several inches above the conveyor allows continuous process monitoring. Users can control moisture/resin content manually or automatically in the OSB process.

If the IR-3000 Oriented Strand Board Moisture Sensor must be installed close to a dryer outlet where it may be susceptible to extreme heat conditions, cooling the sensor with either air or water may be necessary. Trust MoistTech Corp for superior moisture control solutions.

Contact

We offer service and support throughout the world for our moisture measurement sensors and would be happy to connect you with a rep in your area. Contact us today for more information!

Understand the Process

Do you know how beneficial moisture control is? Reduce dryer usage and energy costs by knowing the exact temperature the dryer should be for optimal energy usage. Quality products will become consistent with 100% inspection. Purchase costs can be reduced from water weight.