If you are in the bakery production industry, you know moisture can greatly affect your product and your production. MoistTech Corp. provides superior moisture measurement and control for a variety of industries, including bakery dough production. Our near-infrared (NIR) technology is a non-destructive and non-contact way to accurately measure, analyze, and control moisture with instantaneous data available to ensure your bakery production does not suffer waste or delay. Keep reading to learn more about how MoistTech’s innovative technology can help your bakery dough production reach new qualities, production efficiency levels, and profit.

How Moisture Levels Affect Bakery Dough Production

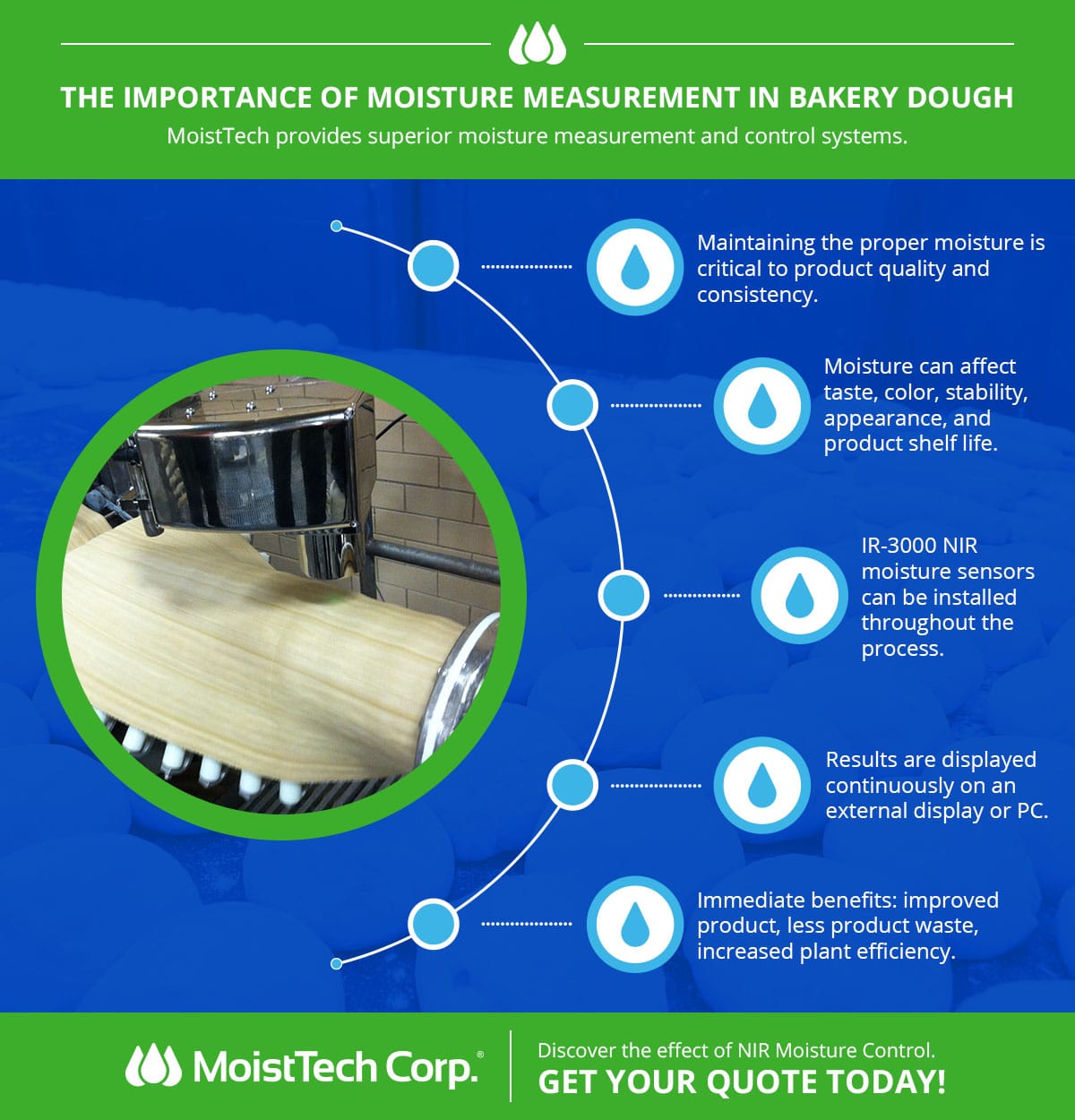

Maintaining the correct moisture content in bakery dough is critical to its quality and consistency, as well as preventing product wastes and cutting your energy costs during the drying and baking phases. Having the incorrect moisture levels in bakery dough can also affect the color, taste, appearance, stability, and shelf life of your product, ultimately affecting customer satisfaction.

Finished bakery dough products rely heavily on having a properly controlled moisture content, as some food items are sold by weight, which could increase or decrease the cost depending on the amount of moisture your product retains. Moisture also affects the fat content, lowering it, reducing the carbohydrates. Too much moisture for your bakery dough products creates a stale taste and can even cause bacteria and mold to populate.

When working in the bakery production industry, properly and effectively monitoring the moisture levels allows precise control over the ovens, optimizing production while reducing energy consumption.

MoistTech’s IR-3000 NIR Installation Process

MoistTech’s NIR technology moisture sensors can be installed before or after the oven, into any hopper, silo, material line, belt, or screw conveyor, giving you the optimal moisture measurement at any point of the bakery dough production. The moisture measurement results are displayed on an external display or PC. By installing MoistTech’s IR-3000 NIR moisture sensors after the dough mixer or after the dough has been formed, manufacturers can continuously monitor the moisture levels and adjust as needed.

Immediate Benefits

An ideal moisture management system detects moisture at various points during the production process and is unaffected by the conditions of the manufacturing factory or plant. Some immediate benefits are:

- Improved Product Quality

- Lower Waste & Energy Costs

- Process Optimization

- Increased Plant Efficiency

- Dryer Control

- Reduced Downtime

Moisture Measurement & Control from Lab to Line

At MoistTech we understand having reliable, accurate moisture control is critical to the success of your bakery dough production, which is why our technology maintains an accuracy level of about 0.1% depending on the application. MoistTech’s IR-3000 moisture sensors are specifically designed to operate unaffected by ambient light or material variations, providing manufacturers with continuous, repeatable, accurate readings. Discover the effect of NIR moisture control, get your quote today!