For manufacturers, considerations must be made for controlling the amount of moisture and oil in crackers and biscuits. Too little or too much will negatively affect production and quality and result in financial loss and lower efficiency. At MoistTech Corp, we utilize near-infrared (NIR) technology that allows for a non-contact solution to provide accurate moisture content readings in these foods. Contact us for more information about installation and application and keep reading to learn about the features and benefits of our IR-3000 series of moisture sensors.

Avoid Poor Quality

Testing moisture during baking allows adjustments to be made so that manufacturers can produce the highest quality crackers and biscuits. Without proper analysis of moisture and oil levels, fryers and ovens can yield variations in quality and consistency, resulting in poor taste, appearance, stability, and shelf life. MoistTech moisture sensors provide accurate readings and continuity that improve the manufacturing process and products.

Various Installations

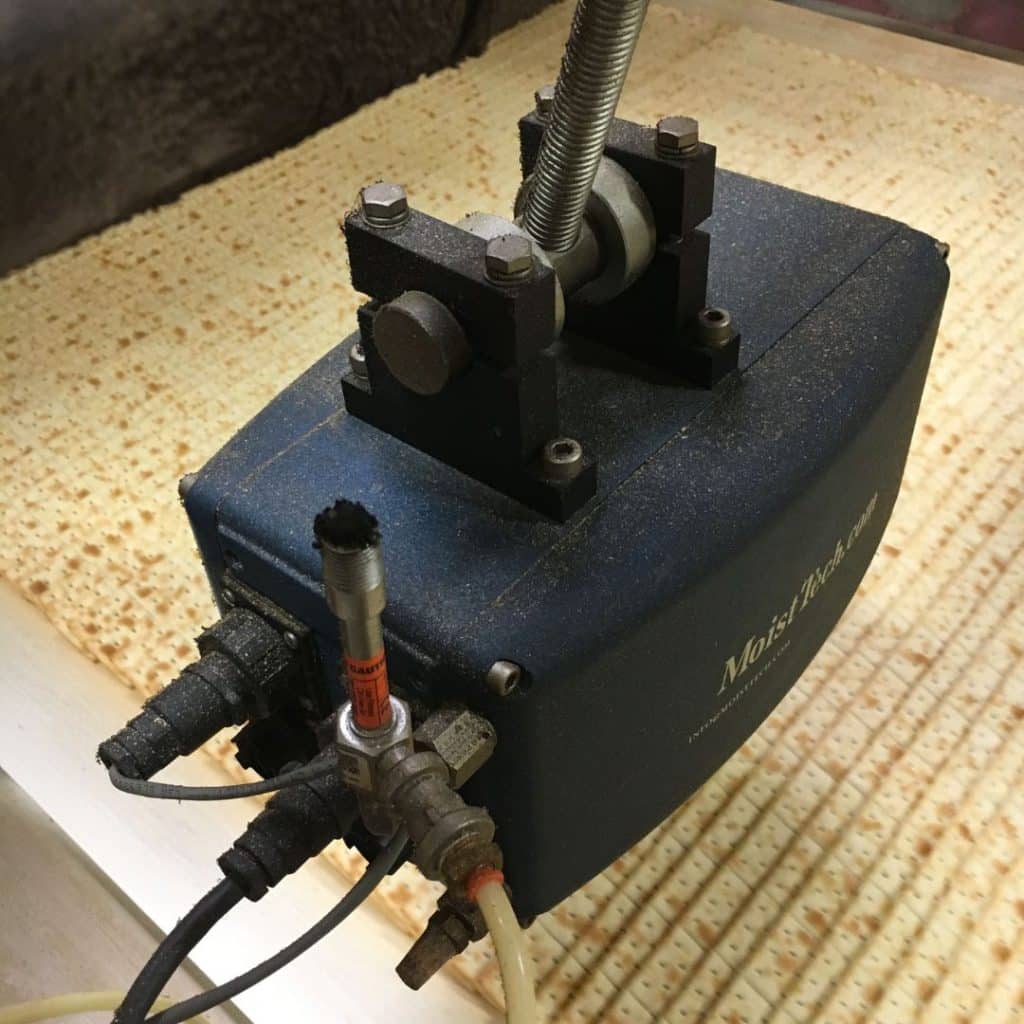

You can install MoistTech on-line moisture sensors into any of your existing hoppers, silos, belts, and screw conveyors. With these sensors installed, you’ll be able to view the results on either an external display or your PC. An ideal moisture control system accurately detects the moisture levels at different stages of the process, is easily maintained, and can withstand even the harshest of manufacturing conditions.

Important Benefits

Installing a moisture measurement and control system prevents poor-quality products due to undesirable moisture levels. More specifically, some of the resulting benefits of moisture measurement and control include:

- Improved Product Quality

- Lower Waste & Energy Costs

- Process Optimization

- Increased Plant Efficiency

- Dryer Control

- Reduced Downtime

Advanced NIR Technology

Our IR-3000 series of sensors are insensitive to material variations such as particle size and color, provide reliable readings with zero drift, and never require maintenance. A one-time calibration with a non-drift optical design allows operational personnel to make immediate line adjustments based on real-time measurements. This near-infrared (NIR) technology provides continuous, repeatable, accurate readings to improve the manufacturing line and product.

Discover the effect of NIR moisture control from MoistTech Corp and improve the manufacturing quality and efficiency of your cracker and biscuit production. Contact us for more information or to get your quote today.