Moisture measurement is critical for product quality and waste reduction, but moisture sensors can be time consuming to install, resulting in lengthy workflow disruptions. With MoistTech, you can eliminate prolonged downtime and enjoy easy moisture sensor installation thanks to plug-and-play technology. Increase production line efficiency and improve product quality consistency with a moisture sensor from MoistTech.

How Plug-and-Play Technology Works

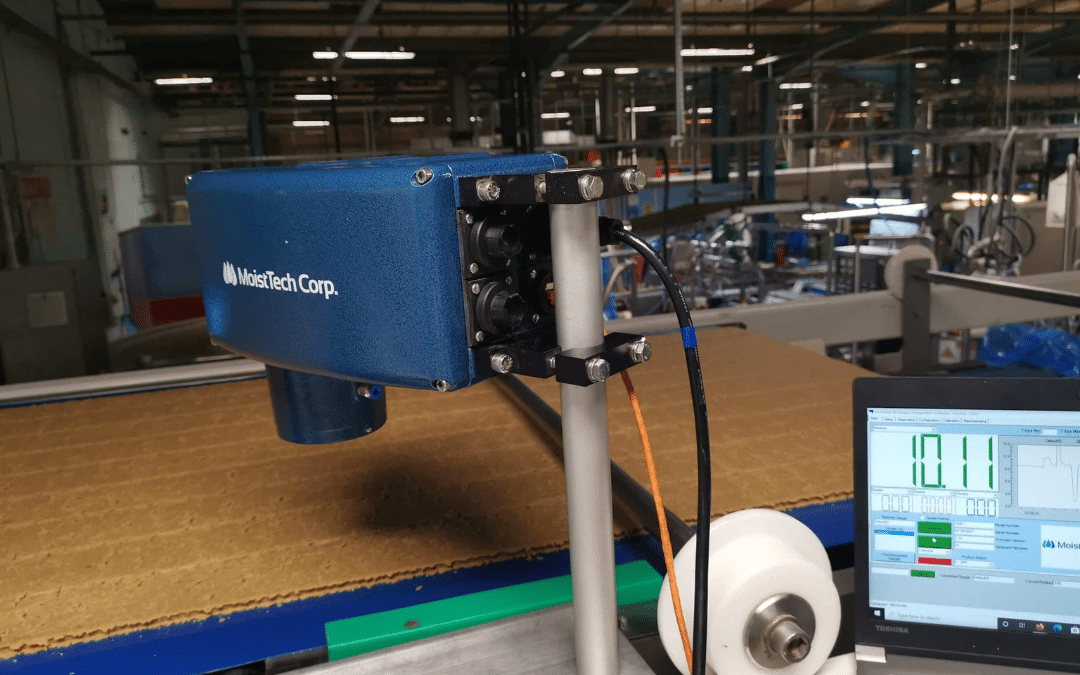

Say goodbye to complicated sensor installation processes that cut into production time. Plug-and-play technology provides seamless integration advantages for moisture sensors. Efficiency is at the top of the list as there are limited workflow interruptions. Where other sensors require downtime for installation, MoistTech’s sensors can simply be plugged in and operational within minutes. Due to the ease of installation, MoistTech sensors can be installed nearly anywhere on the production line. Popular installation locations include conveyors, chutes, cyclones and bins. The sensors are usually mounted 4”-16” from the product flow that is being measured. No matter if it is open air or enclosed, the sensors can be installed wherever there is a power source. With the simple installation process, the production line can remain running at peak efficiency without workflow stoppages.

Additional MoistTech Benefits

MoistTech has numerous years of engineering experience. We draw from this knowledge when creating moisture sensors that provide solutions for production line challenges. In addition to reducing downtime for installation, there are several benefits to a moisture sensor with plug-and-play technology. These all play a role in streamlining production and ensuring product consistency.

- Non-contact measurements

- Instant measurements

- No drift

- Never needs calibrating

- Low maintenance

Near-Infrared Moisture Sensors

MoistTech’s plug-and-play moisture sensors use near-infrared (NIR) technology. NIR sensors provide accurate, reliable and repeatable results. The non-contact measurement feature means there is no product waste when collecting samples. Additionally, line downtime is not required to gather data, as the sensors are continuously monitoring the moisture content of product. If an out of spec moisture level is detected, the operator can quickly make adjustments to prevent product waste and maintain a high level of quality. MoistTech’s moisture sensors combine technology with innovation for solutions to efficiently challenges.

Moisture Sensor Industries

Nearly every industry whose product can be altered by moisture content can benefit from a plug-and-play moisture sensor. From food products to wood pulp, moisture sensors can aid in the improvement of quality, effectiveness and product consistency. Maintaining correct moisture levels can also increase plant safety by preventing dust explosions and similar events. These are some industries that can be assisted by a MoistTech moisture sensor.

- Animal food

- Human food

- Snack food

- Bioenergy

- Tobacco

- Wood

- Pharmaceuticals

- Chemicals

- Textiles and non-wovens

Receive a Quote Today

A plug-and-play moisture sensor can boost product quality while cutting back on workflow interruptions. Let’s discuss your MoistTech installation. Request a quote today.