Moisture Measurement from Lab to Line

Near-infrared, no-contact moisture measurement technology

Get a QuoteMoistTech Provides Instant Process Optimization with Moisture Monitoring

MoistTech Corp. is the diamond standard for robust, reliable, and dependable near-infrared (NIR) moisture measurement technology. We manufacture on-line and at-line instruments to monitor moisture for a range of industries. By continuously monitoring moisture content, this allows for real-time processing control, leading to improved quality, less downtime and reduced waste. Any application that relies on precision moisture measurement can benefit from a MoistTech sensor.

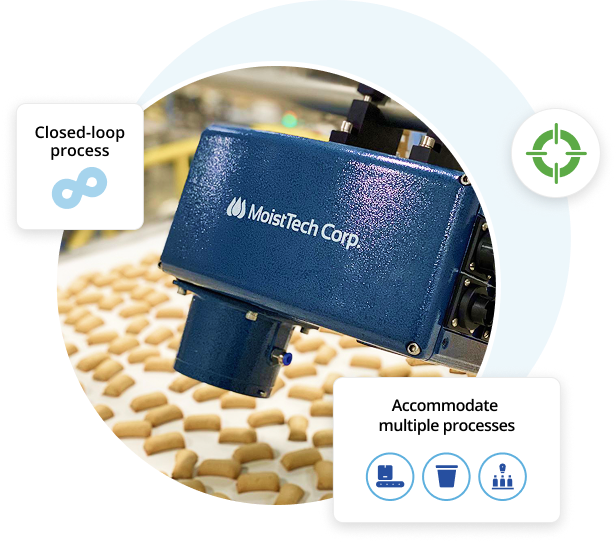

Eliminate Human Error for Full Control Over Your Production

Out-of-date manual processes are time consuming and can involve human error. Incorporating moisture measurement during production allows users to create a closed-loop process and have full control over the production line. MoistTech’s near-infrared equipment can easily accommodate multiple processes including pneumatic conveying systems, belts, screws, chutes, bins, buckets and vibratory.

Moisture Measurement is an Investment that Pays for Itself

Creating a closed-loop process by incorporating the unit with your PLC allows users to make line adjustments, such as product flow rates, dryer temperatures, dampeners, etc. to achieve optimal and continuous targeted moisture levels. Reading and controlling moisture levels is an invaluable part of the manufacturing process and can pay for itself in months.

Explore the IR-3000 Difference

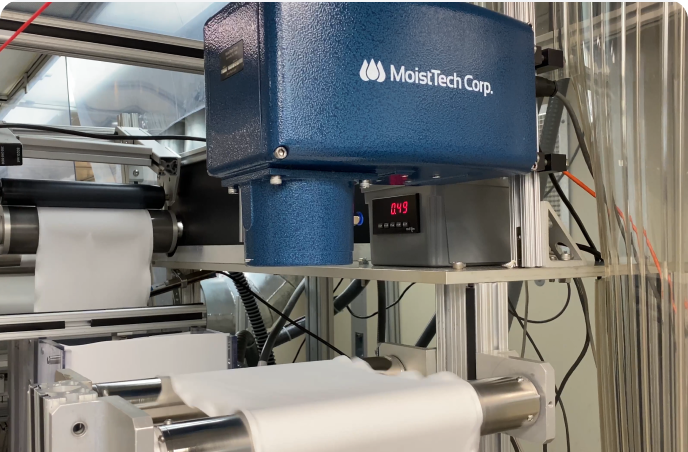

Insensitive to material variations, such as particle size, material height and color, MoistTech developed the IR3000 series of online sensors for instant, non-contact measurement in the harshest manufacturing environments. Continually monitoring moisture levels allows operating personnel to confidently make immediate process adjustments based on real-time measurements.

Easy to Install and Maintain

Time and Material Savings

Innovation and Reliability

Featured MoistTech Applications

Mineral, Mining, and Bulk Materials Moisture

Snack Foods Moisture

Animal Foods Moisture

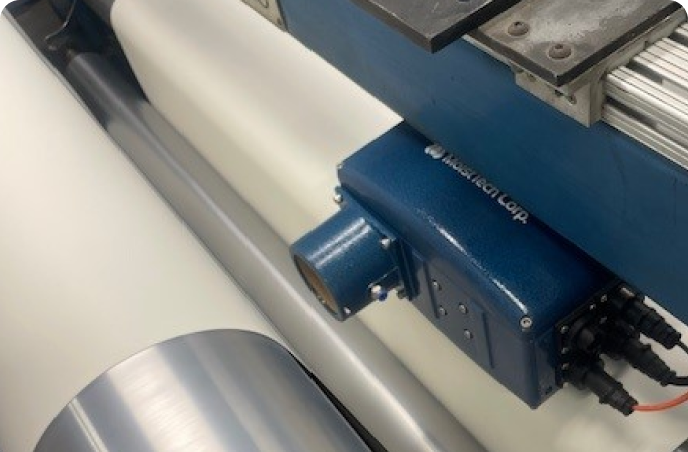

Converting Moisture & Coating

Wood Products Moisture

Textiles/Nonwovens Moisture

Bioenergy Production Moisture