Uncategorized

-

MoistTech is Headed to PACK EXPO Las Vegas 2025 – See Us at Booth N-7130!

MoistTech is excited to announce our return to PACK EXPO Las Vegas 2025, happening September 29th–October 1st at the Las Vegas Convention Center! As the premier event for packaging and processing innovation, PACK EXPO is the place to see the latest technologies driving efficiency, sustainability, and product quality, and we’re proud to showcase our cutting-edge…

-

Enhancing Efficiency & Cost Savings with Moisture Management

In the dynamic landscape of modern manufacturing, where efficiency and cost-effectiveness are paramount, MoistTech Corp. emerges as a global leader in moisture measurement solutions. Their cutting-edge IR3000 series moisture sensors exemplify innovation, reliability, and significant cost-saving benefits for industries worldwide. The IR3000 series employs state-of-the-art Near Infrared (NIR) technology, enabling precise and continuous moisture analysis…

-

How Moisture Monitoring Prevents Shrinkage and Color Defects

In the textiles and fabrics industries, product quality is paramount. If products do not meet set standards, recycling or discarding may be the only options. Moisture content plays an important role in the product quality of textiles. It can affect the quality, durability, fit and appearance of fabric. Improper moisture levels in textile production can…

-

Why Accurate Moisture Measurement Is Essential for Quality and Efficiency in Industrial Baking

The benefits of the IR3000 extend beyond moisture measurement, contributing to overall process optimization and cost reduction. By enabling real-time adjustments to production processes, operators can proactively address issues and minimize downtime and waste. Additionally, continuous NIR online moisture testing allows for precise control of ovens and dryers, optimizing energy consumption and leading to substantial…

-

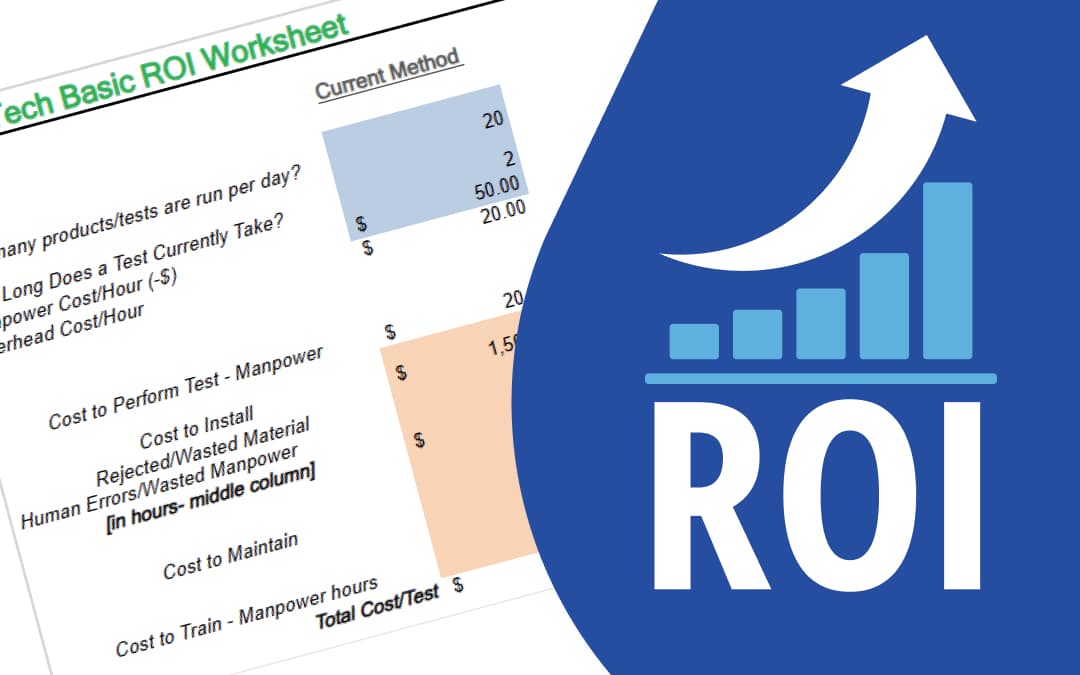

Enhancing Efficiency and Cost-Savings with MoistTech’s IR3000 Series Moisture Sensors

In the dynamic landscape of modern manufacturing, where efficiency and cost-effectiveness are paramount, MoistTech Corp. emerges as a global leader in moisture measurement and control solutions. Their cutting-edge IR3000 series moisture sensors exemplify innovation, reliability, and significant cost-saving benefits for industries worldwide. MoistTech Advantages The IR3000 series employs state-of-the-art Near Infrared (NIR) technology, enabling precise…

-

Increasing Snack Food Production with Moisture Measurement

Collecting moisture and oil measurements during snack food production can offer several benefits. When moisture and oil data are available in real time, the operator can make adjustments quickly to resolve any issues. This leads to improved product quality, less waste and more satisfied customers. Snack foods, such as crackers, potato chips, pretzels and breadsticks,…

-

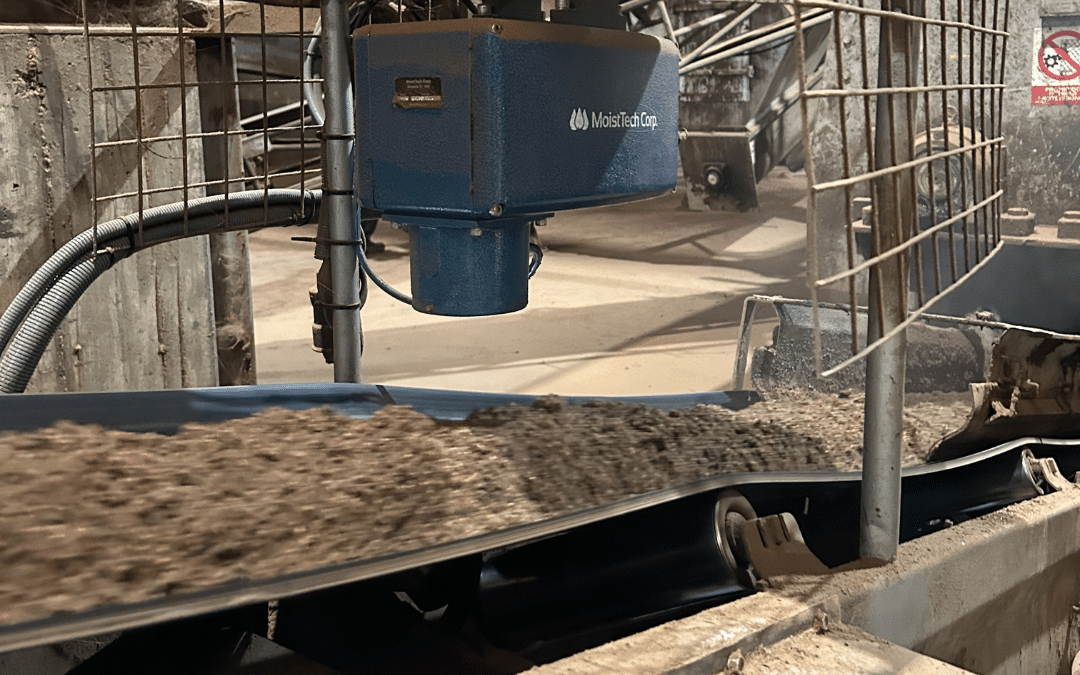

Reducing Energy Costs in Powders and Bulk Solids Production Processes

Powder and bulk solids manufacturers can incur high energy rates due to the nature of production. From industrial dryers to rotary kilns, there are several pieces of essential equipment that consume high volumes of energy. When the material has an improper moisture content, it can lead to extended use of this equipment and higher energy…

-

Moisture Measurement Can Prevent Dust Explosions in Powder Bulk Solids Industry

Improper Moisture Control Contributes to Dust Explosions Precision moisture control plays a significant role in the powders and bulk solids industries. If a line has improper moisture levels, it can lead to product waste, unnecessary downtime and even safety hazards. A major concern of improper moisture levels is a dust explosion, which can seriously damage…

-

Precision Moisture Measurement for Food Manufacturing Company Case Study

Precision Moisture Measurement In food production, it is important to have correct levels of moisture. Too much or too little moisture can affect product quality. By using a MoistTech moisture sensor on-line, moisture levels can be adjusted in real time, which leads to improved product quality, less material waste and more efficient production. The Background…

-

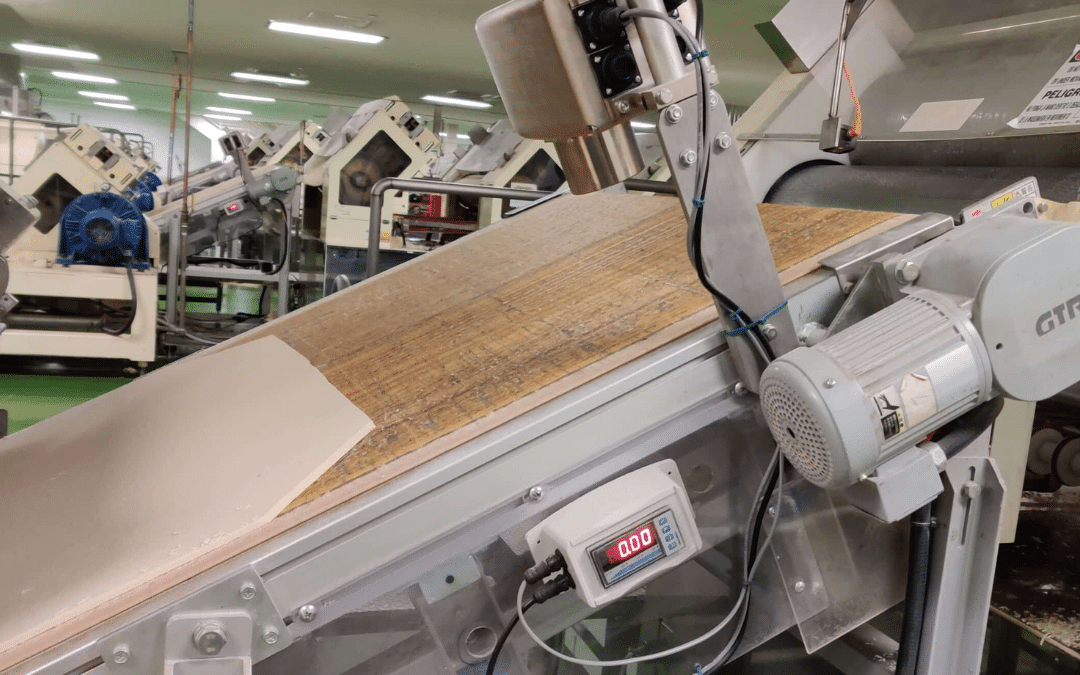

Precision Moisture Measurement for Wood Manufacturing Company Case Study

Precision Moisture Measurement Inaccurate moisture levels can lead to multiple issues in the wood manufacturing industry. By using a precision moisture sensor from MoistTech, the moisture levels can be measured, and alterations can be made as needed. The sensor can stand up to harsh conditions to help improve product quality. The Background An Oregon-based manufacturer…

-

The Ultimate Guide in Choosing the Right Moisture Measurement Device for Wood

Incorrect moisture levels can cause major issues for wood. From strength and drying problems to bond and glue curing complications, excessive moisture can wreak havoc. These issues can be avoided with a moisture measurement system. By using a sensor to measure moisture content in wood, you can improve the quality of your wood product, reduce…

-

Key Factors to Consider When Integrating Moisture Sensors into Your Production Line

[et_pb_section fb_built=”1″ _builder_version=”4.25.2″ _module_preset=”default” global_colors_info=”{}”][et_pb_row _builder_version=”4.25.2″ _module_preset=”default” global_colors_info=”{}”][et_pb_column type=”4_4″ _builder_version=”4.25.2″ _module_preset=”default” global_colors_info=”{}”][et_pb_text _builder_version=”4.25.2″ _module_preset=”default” hover_enabled=”0″ global_colors_info=”{}” sticky_enabled=”0″] Measuring moisture content is crucial to many different industries. Even a slight variation in moisture content can cause quality issues with products. A moisture sensor can resolve the issue of moisture detection using near-infrared technology to accurately indicate…