MoistTech is Manufacturing’s Moist Valuable Player

Moisture Control Creates Instant Process Optimization

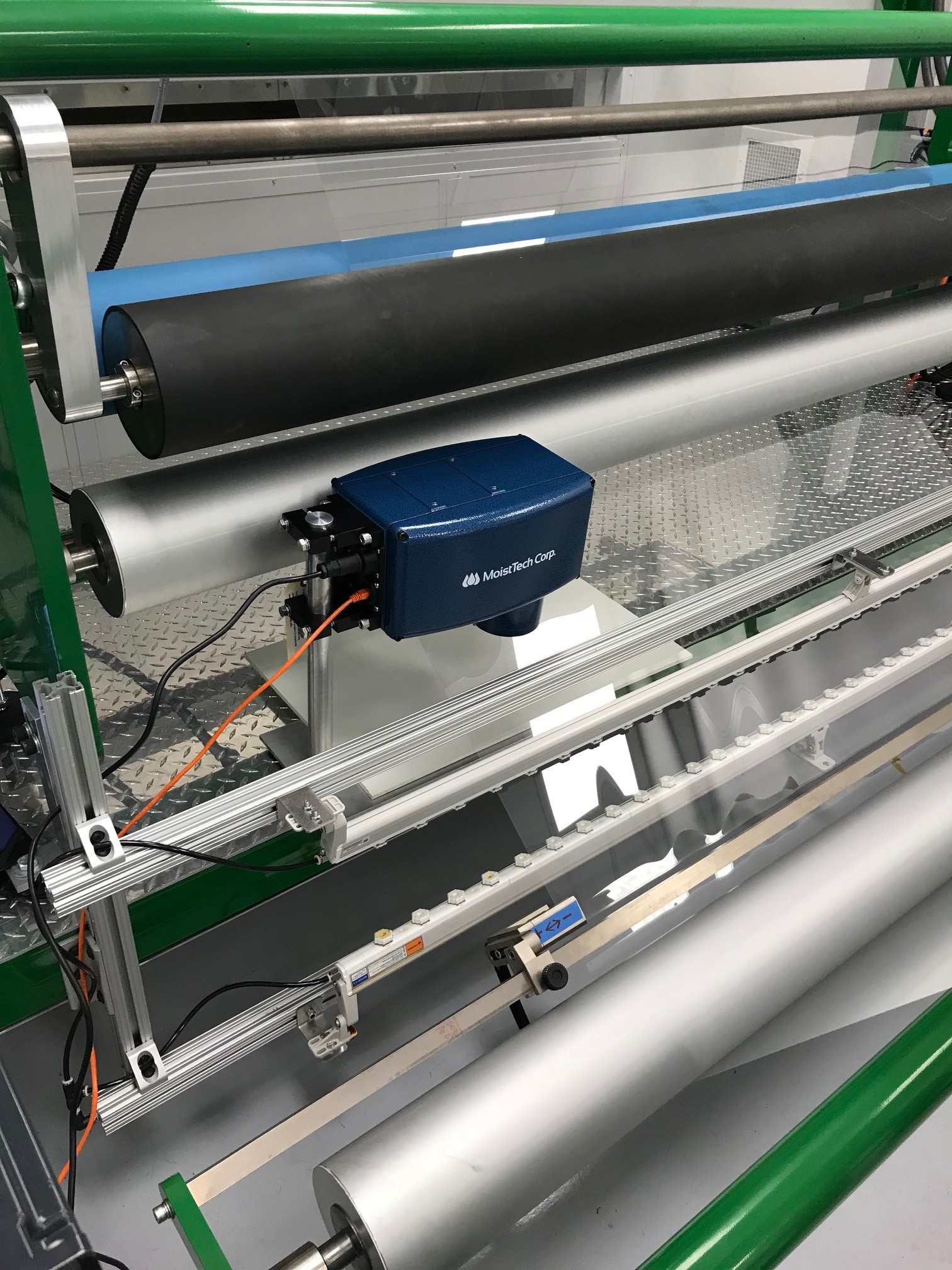

For decades, the manufacturing industry has been plagued by common issues such as wasted product, low-efficiency and lack of consistency. MoistTech provides a top of the line solution for these issues by providing a fast and easy set up that is installed over the production line with a non-contact reading. Near-infrared technology is ideal for a quick, easy, reliable moisture reading to quickly optimize the manufacturing process.

Real-Time Process Control

Capable of providing true data regardless of gaps and interruptions in product flow, these sensors are insensitive to material variations, such as height, color and particle size. Consequently, MoistTech equipment can deliver instant, non-contact moisture analysis of manufactured goods to ensure the accuracy and quality of the final product. Not only does this make for a reduction in waste, but also a decrease in downtime, manual intervention and defective goods.

Diverse Applications

Serving a wide variety of sectors and disciplines, including adhesives, biomass, chemicals, coatings, food, forest products, minerals, renewable energy, textiles and wood products, MoistTech solutions are valued by a diverse range of clients. Alongside the firm’s flagship IR3000 sensor, which can be used for most applications, the company offers a number of more specialist products

Always innovating, MoistTech has been responsible for some of the indsutry’s most advanced technological developments over the years. Since the beinning, MoistTech has been the #1 name for industrial moisture control.

Unmatched Service & Support

Beyond the company’s inherent technological advantage, MoistTech also provides some of the industry’s best customer service and on-site support. For instance, once samples are received and a calibration is built, the firm endeavors to have its clients in operation within two weeks of their initial order.

When it comes to customer service and support, we are hard to beat!

Results.

MoistTech NIR technology is a ratio-based measurement with prime beam, which eliminates sensitivity to distance, improves stability and accuracy, and provides a non-drift design. This allows for extremely accurate measurements with far more sensitivity than that of the firm’s competitors. While other technologies require constant re-calibrations, have height interference, experience drifting over time, and produce less reflected light, MoistTech solutions provide the user with true data rather than an estimated guess.

Moisture control is essential in the manufacturing process as the presence of moisture in just one part of the processing line can result in wasted product and downtime. MoistTech provides reliable and accurate solutions for moisture control through NIR technology, which can measure the level of moisture within a manufactured product. These instant measurements can result in big savings all around. Call us today to receive a no-obligation quote.