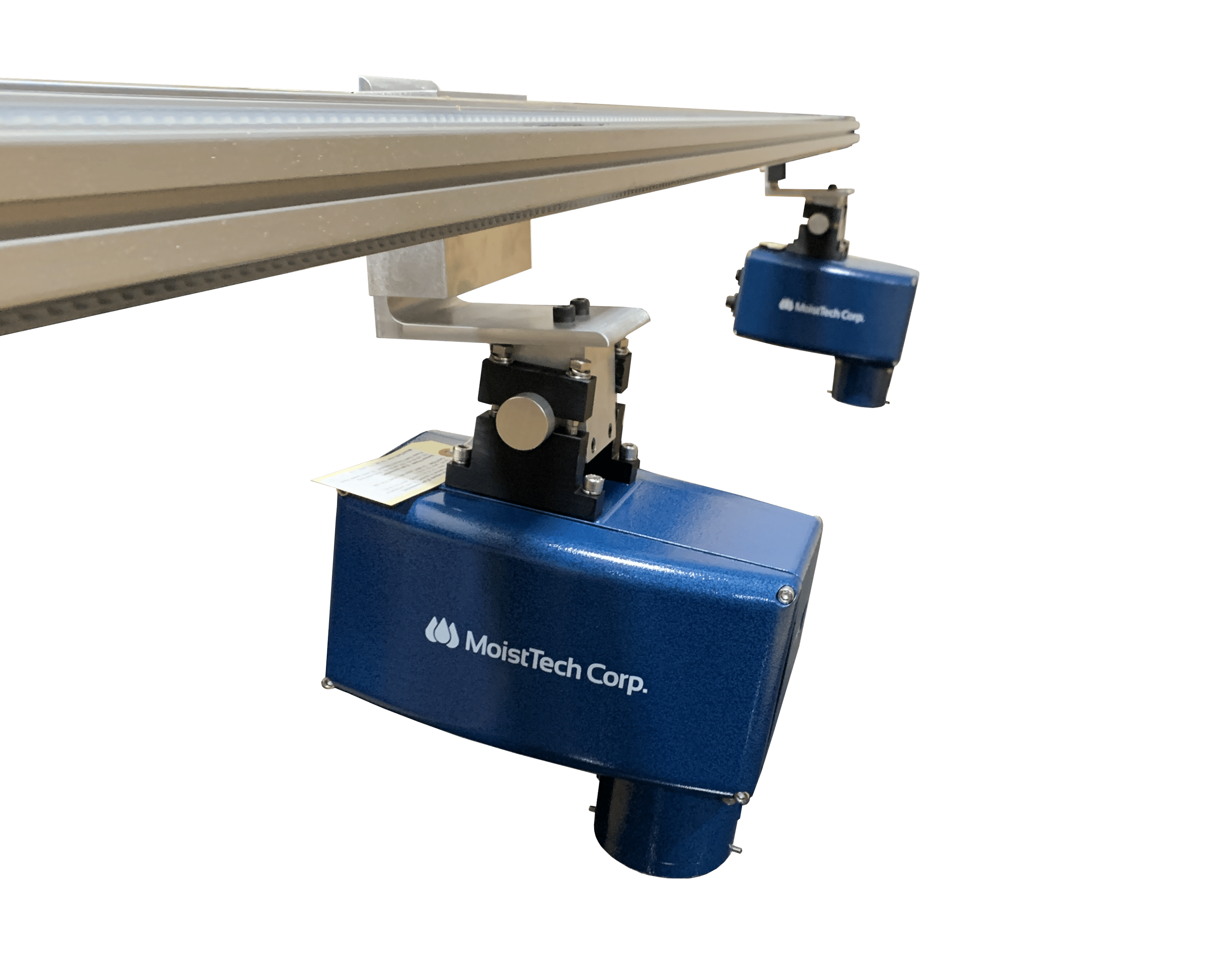

We offer continuous moisture measurement and control in all aspects of the manufacturing process and now the Linear Belt Driven Slide system can offer measurement across a web. A custom sized traversing slide that can hold multiple moisture units provides users with complete measurement data that allows for full quality control over the line.

State of the Art Reliability

MoistTech’s near-infrared moisture and coating measurement systems are the top answer for immediate, non-destructive analysis during the manufacturing process. With spot test measuring, it can becomes a challenge in a handful of applications – which is why MoistTech has debuted the Linear Belt Driven Slide as a way for users to establish the true data readings across the web. Used in paper, plastic, extruding and similar applications, a traversing slide allows more than one sensor to be simultaneously moved across the material to provide an accurate look at the entire process, ensuring the quality control. With an instant, inline ability to measure the moisture content and determine coat weight, manufacturers can easily create a closed loop process, feeding all data back to the PLC.

Designed to provide accuracy and repeatability, the MoistTech NIR technology is a ratio-based measurement with prime beam; this eliminates sensitivity due to distance, improves stability and accuracy. The technology captures hundreds of detailed, accurate measurements per second. The ability to pre-set the measurement rate to match the production rate is available on the technology and because there are no routine re-calibrations, this technology is low to zero maintenance which makes it an ideal solution for the manufacturing process.

Customized Solutions

The Linear Belt Driven Slide systems are all custom ordered so they are made to fit your exact specifications and manufacturing line perfectly. Our engineering team can help determine the best system and moisture sensor setup to fine tune your process to create the ideal quality product. Our diamond standard moisture and coat weight measurement systems will provide increased efficiency, less waste and downtime, improved productivity and reliability.

Insensitive to material variations such as particle size, material height & color, our moisture sensors provide continuous, reliable readings with zero maintenance and a one-time calibration with a non-drift optical design allowing operational personnel to confidently make immediate process adjustments based on real-time measurements.

Discover the Effect of NIR Moisture Control

If you’d like to learn more about how MoistTech can help with moisture measurement in sugar production, contact us today. We’d be happy to discuss our products and technologies with you and answer any questions you may have.