Manufacturing’s MOIST Valuable Player

MoistTech Continues to Stand Above the Competition

Having forged its reputation as a solutions provider for many common production line problems, MoistTech has grown into a world leader in moisture measurement and control. For decades, the manufacturing industry was plagued by common issues, such as wasted product, low-efficiency and a lack of consistency. John Fordham and Roger Carlson recognized the need for solutions, and in 1975, founded a company that could provide them – MoistTech.

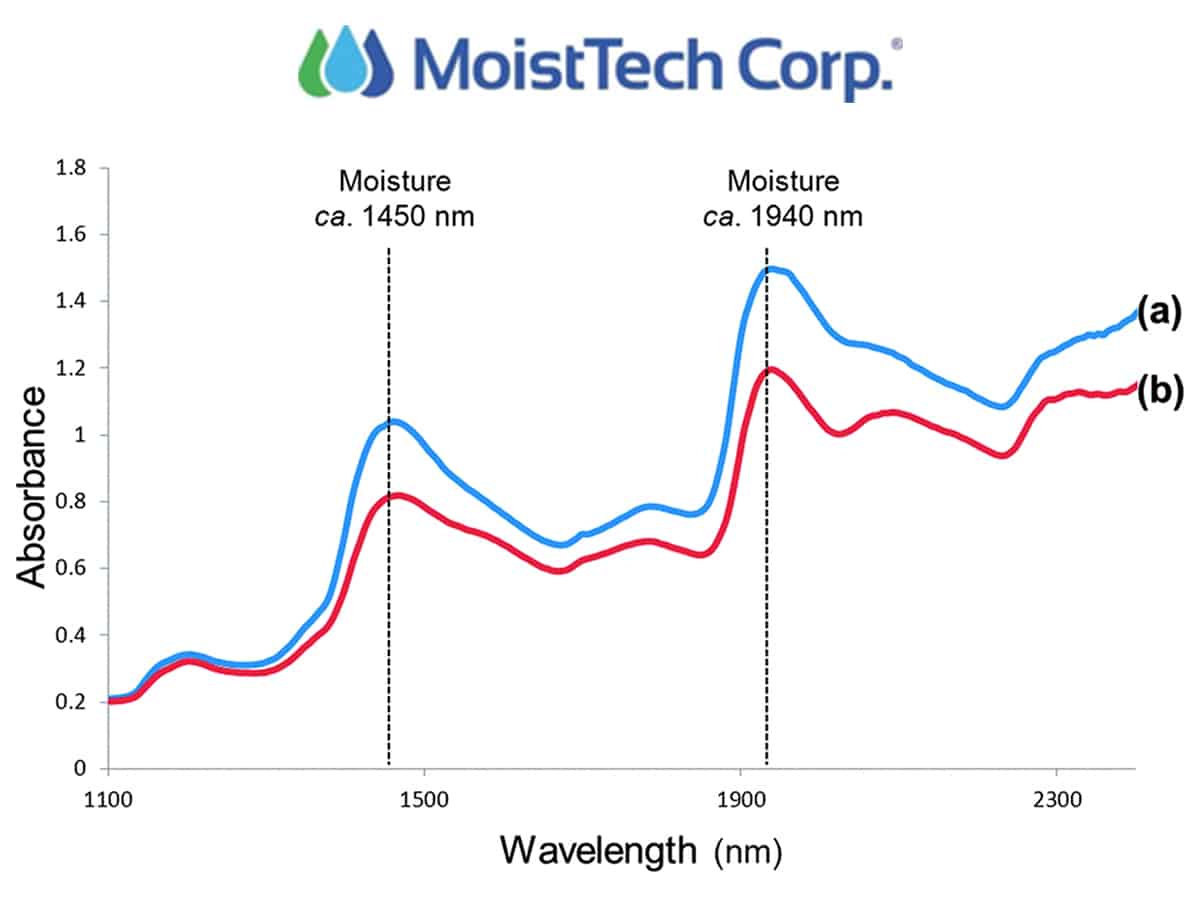

Established in Sarasota, Florida, MoistTech is responsible for the industry’s first patented method of non-contact, non-destructive moisture analysis and detection for a multitude of sectors. Improved over time, the company’s near-infrared (NIR) technology still leads the market in 2021, providing robust and reliable moisture measurement and control for businesses the world over.

Undeniable Results.

Primarily, MoistTech manufactures a substantial range of on-line and at-line sensors for the real-time process control of numerous applications. Capable of providing true data regardless of gaps and interruptions in product flow, these sensors are insensitive to material variations, such as height, color and particle size. Consequently, MoistTech equipment can deliver instant, non-contact moisture analysis of manufactured goods to ensure the accuracy and quality of the final product. Not only does this make for a reduction in waste, but also a decrease in downtime, manual intervention and defective goods.

Endless Applications.

Serving a wide variety of sectors and disciplines, including adhesives, biomass, chemicals, coatings, food, forest products, minerals, renewable energy, textiles and wood products, MoistTech solutions are valued by a diverse range of clients. Alongside the firm’s flagship IR3000 sensor, which can be used for most applications, the company offers a number of more specialist products.

“We have the CCS3000 for dark materials like coal, the IP67 for harsh conditions, the 828-model designed specifically for tobacco and less sensitive blends, and two laboratory units that are considered ‘at-line’: which are the 868 and 858 models,” John remarks. “The IR3000, however, is our most state-of-the-art smart sensor. For any application, it will have a measuring and repeatability accuracy in the +/- 0.05 per cent range depending on the application specifics. The sensor is drift free and recalibration will never be required. As standard, there are three isolated 4-20mA outputs along with an Ethernet connector and a second one for RS-232/485 serial communication. For display, included in the quotation as an option, is a remote LED meter with 3.5-inch digits for excellent readability.

Better Accuracy Than The Competition

MoistTech NIR technology is a ratio-based measurement with prime beam, which eliminates sensitivity to distance, improves stability and accuracy, and provides a non-drift design. This allows for extremely accurate measurements with far more sensitivity than that of the firm’s competitors. While other technologies require constant re-calibrations, have height interference, experience drifting over time, and produce less reflected light, MoistTech solutions provide the user with true data rather than an estimated guess.

Saves Costs

“Central to our success is the fact that we have more advanced design than our closest competitors, giving us much more reflected NIR energy to the product, less height interference and, most importantly, one-time calibration with zero drift,” John says. “MoistTech is the original pioneer of NIR and we still have the backing of the patent holder for the principle, which means there’s much more to come.”

Always innovating, MoistTech has been responsible for some of the industry’s most advanced technological developments over the years. Together with Co-Founder and Head of Engineering Roger Carlson, John has overseen them all.