Maximize Production with Low Cost & High Accuracy

increases plant efficiency

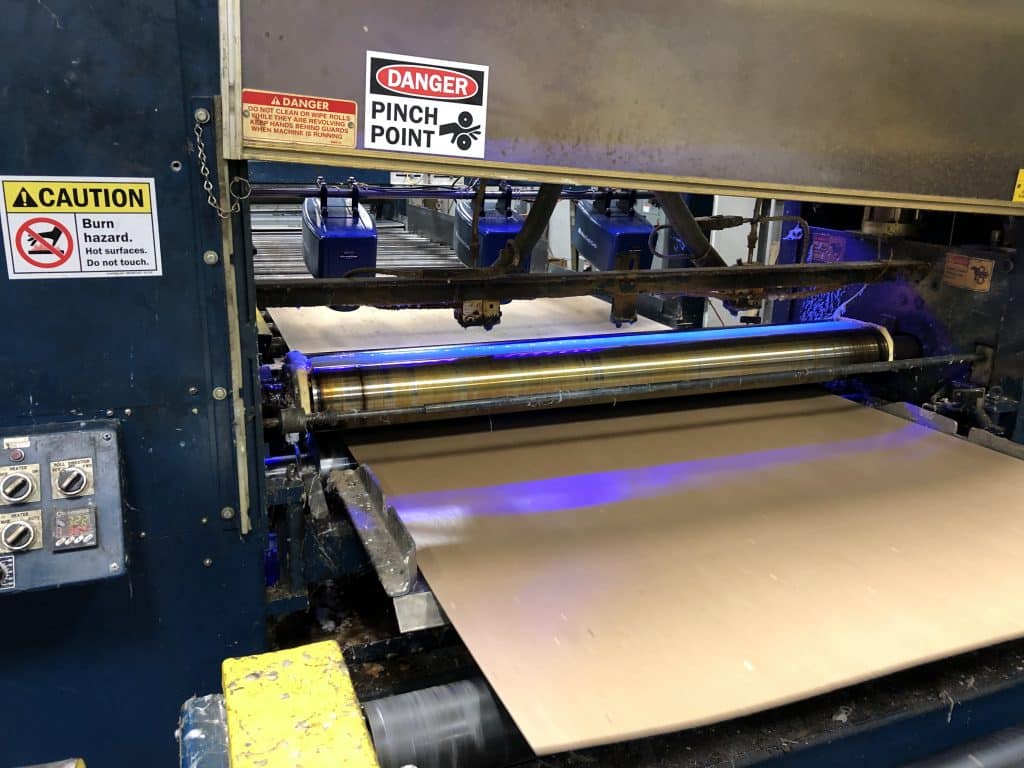

Moisture measurement and control analyzers can be found in thousands of applications all over the world, saving manufacturers a large amount of time and money by quickly detecting out of specification moisture ranges on the manufacturing line. Operating personnel can make immediate line adjustments based on real-time data. MoistTech Corp. has introduced Near-Infrared (NIR) technology to the moisture measurement and control process by producing the diamond standard in process control.

Improved Product Quality Monitoring

During various stages of processing, moisture levels are critical as the product can quickly become too wet or dry, wasting time, effort, and product. An ideal moisture control system accurately detects the moisture levels at different stages of the process, is easily maintained and has the ability to withstand even the harshest of manufacturing conditions. The IR3000 series of on-line sensors manufactured by MoistTech are specifically designed to be unaffected by ambient light, material variations such as particle size, material height and color, and provide continuous, repeatable accurate readings.

Lower Energy Costs & Less Waste

With a non-drift optical design and low to zero maintenance, MoistTech’s IR3000 sensor provides immediate process adjustments to increase efficiency and minimize costs. Implementing production operations to improve the process with proper moisture control begins with a non-contact, pre-calibrated, plug and play solution that is easily incorporated into the manufacturing line with no downtime.

The ability to reduce waste and keep the production line moving is essential to plant operators. Moisture measurement and control plays a large role in this ability. With the implementation of MoistTech’s IR3000 system, plants can now make major reductions in waste – wasted time, wasted effort and wasted product. Catching out of tolerance readings as quickly as possible allows for the most opportune ways to increase plant efficiency.

- Reduce Start Up & Down Times

- Reduction of Wasted Product, Time & Effort

- Reduced Energy Usage

- Consistency of Final Product

- Increased Productivity

- Minimize Costs with Implemented Process Control

Process Optimization

The on-line sensors are mounted several inches above the material and can be placed before or after the dryer, on a belt, screw or drag conveyors, chutes, cyclones and bins, pipelines, and pneumatic conveying as well. The MoistTech sensors are not limited to the type of installation and can be mounted in any orientation using many of our measurement accessories. Typical analog range is 1-10% moisture with 0.1-0.2% accuracy.

MoistTech has designed a suite of high-tech Windows® programs to provide user-friendly interfaces for configuration, data logging, and monitoring of diagnostics.

Our configuration software provides the operator with the capability to monitor up to three constituents and the addition of the temperature option. Output trending is displayed to take corrective action prior to reaching determined thresholds. The MoistTech software is easy to use and compatible with any PC platform.

NIR Technology

NIR technology has both performance and accuracy benefits over competing technologies currently being used to measure moisture content. NIR spectroscopy is a fast, non-destructive method of analyzing the chemical and physical information of a product in virtually any matrix. A light source is used to reveal transmitted light passing through the product, while backscattered light reflects from the product and is absorbed. The moisture content is determined by the amount of light that is absorbed and also reflected back to the sensor.

Other technologies require constant re-calibrations, have height interference, experience drifting over time, produce less reflected light energy and overall provide the user with more of an estimated guess of moisture content rather than true, repeatable data. MoistTech’s technology provides hundreds of readings per second with the ability to be displayed anywhere throughout the process, giving full access and capabilities to the production line.

With the ability to store up to 50 product / calibration codes, line operators can alert the sensor for changing products immediately. Streamlining the production process to include the ease of measurement not only improves the final product but allows the plant to operate more efficiently, experience less downtime and increased production.

Additional Benefits:

Immediate results can be seen when proper moisture measurement and control technology is used:

- Newest Technology & Software

- Surface Mount Electronics

- Unlimited Licensing – Display readings in as many places as needed

- Process Optimization

- Low to Zero Maintenance

- Fuel Consumption & Water Savings

MoistTech is a leading global manufacturer of Near-Infrared Moisture Measurement Sensors and equipment; first established by Director John Fordham alongside two other fellow engineers. The company have their head office based in Sarasota, FL, which covers North & South America, and other locations across Asia, Africa, the Middle East, and Europe. Learn more about how the IR-3000’s moisture technology can simplify the manufacturing process: +1 941-727-1800 info@moisttech.com / www.moisttech.com

Follow us on social media for more info. Contact our corporate office today to see how proper moisture measurement and control can have a drastic effect on your production line: info@moisttech.com or 941-727-1800